The Gasjackchen (gas jacket) was a German gas mask introduced in 1940. The concept behind it was very simple: babies tend to be (relatively) compliant, whereas anyone with a toddler will testify that some aspects of their behaviour can leave a great deal to be desired, let alone be rational. So uniquely, this factor was considered by the Germans when they developed gas masks for the wider population.

In order to bridge the gap between the Gasbettchen (gas cot) and the standard civilian gas masks, the Gasjackchen was developed. Produced in two main styles, these were provided for all children up to and including the age of four.

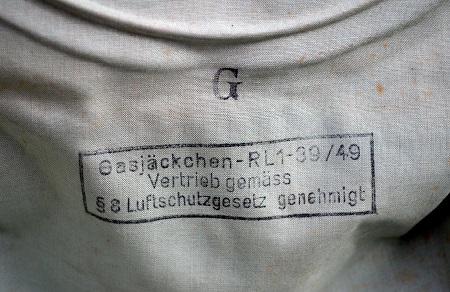

The jacket was made of a rubberised material and depending upon which of the two styles supplied, had the filter and air intake either at the front or at the back. The example shown here was producer by Auer and has its entry point at the rear.

The jacket had drawstrings by which the sleeves and waist could be 'sealed' in order to protect the occupant from the ingress of gas. The filtration was achieved by means of a standard civilian filter, attached by means of simply screwing it directly to the end of the air hose inside the jacket. Air was supplied through a set of bellows, which the parent (most usually the mother) would operate.

The jacket had drawstrings by which the sleeves and waist could be 'sealed' in order to protect the occupant from the ingress of gas. The filtration was achieved by means of a standard civilian filter, attached by means of simply screwing it directly to the end of the air hose inside the jacket. Air was supplied through a set of bellows, which the parent (most usually the mother) would operate.

This, in theory, would provide fresh filtered air to create a positive pressure within the confines of the jacket. The hose on the gas cots was of the same type.

The child's exhaled breath would be released by the provision of a one-way valve located just above the facepiece (see photograph). As with all state sanctioned / supplied products, the jacket was subject to a quality inspection and the photograph of the valve clearly depicts the quality approval stamp.

The child's exhaled breath would be released by the provision of a one-way valve located just above the facepiece (see photograph). As with all state sanctioned / supplied products, the jacket was subject to a quality inspection and the photograph of the valve clearly depicts the quality approval stamp.