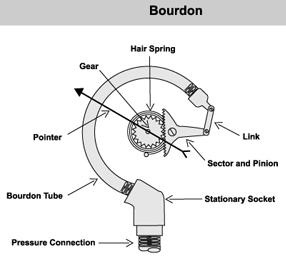

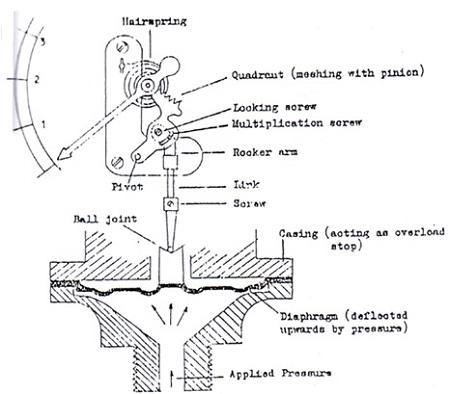

High pressures are typically measured using a Bourdon tube gauge (see the previous page); lower pressures are measured using the Diaphragm gauge. For measuring oxygen, there is an additional aspect, as pure oxygen and any kind of grease/oil, when brought into contact under pressure will result in an explosion! Thus any gauge destined for use in the measurements of oxygen is required to be completely de-greased and certified and marked (on the dial face) as OIL CLEAN. This is indicated by the picture of an oil can overlaid with a cross. The basic operation of the Bourdon tube gauge is shown below. In the instance of the gauge used on our Hurricane, there is the addition of a blow-out plate to the rear. In the event of any kind of damage to the internal mechanism of the gauge, rather than the blast being forced and injuring the pilot, the blow-out simply allows for it to be directed harmlessly to the rear.