The Soviets introduced the TM-35 anti-tank mine in 1935. Around this time, many nations were in the process of developing more effective means of neutralising the potential that the tank posed in combat. Tanks were first developed during WW1; initially, they were (whilst marvels of actual engineering) slow and somewhat crude when compared to what followed. Both passive and active means of dealing with tanks were beginning to come of age during the 1930's, as indeed were the tanks themselves. And while the active means of countering tanks (anti-tank guns) would go on to require ever greater adaption to keep pace with the increase in the armour of the tank, the passive (mines and anti-tank obstacles) would remain reasonably standard from early inception to the modern day.

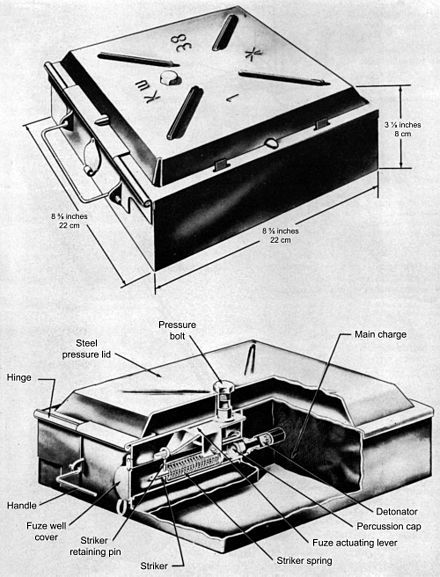

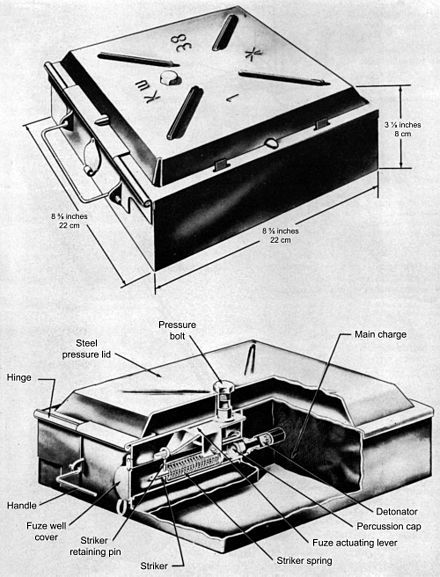

The TM-35 was produced using zinc-plated steel and was rectangular in shape. The pressure plate, on the top, when compressed by the weight of a tank, would in turn depress a rocker switch that would remove an internal safety pin allowing for the MUV* fuse to activate the mine. 200 grams of TNT was packed in blocks, housed in divided sections inside the body of the mine.

The TM-35 was produced using zinc-plated steel and was rectangular in shape. The pressure plate, on the top, when compressed by the weight of a tank, would in turn depress a rocker switch that would remove an internal safety pin allowing for the MUV* fuse to activate the mine. 200 grams of TNT was packed in blocks, housed in divided sections inside the body of the mine.

Externally, the mine was provided with a carry handle for easy of transportation. It also featured four ridges on the pressure plate, which both allowed for the steel to be thinner than would otherwise be the case and acted as an anchor into the soil covering the top of the mine, preventing the wind from exposing the mine's location. Russian soil was generally lighter and finer soils than that of most countries, so this was a very real potential. Additionally, the TM-35 allowed for an additional fuse to inserted, which would work in tandem with the internal MUV full fuse making it harder for attacking troops to render the mine safe in advance of their tanks.

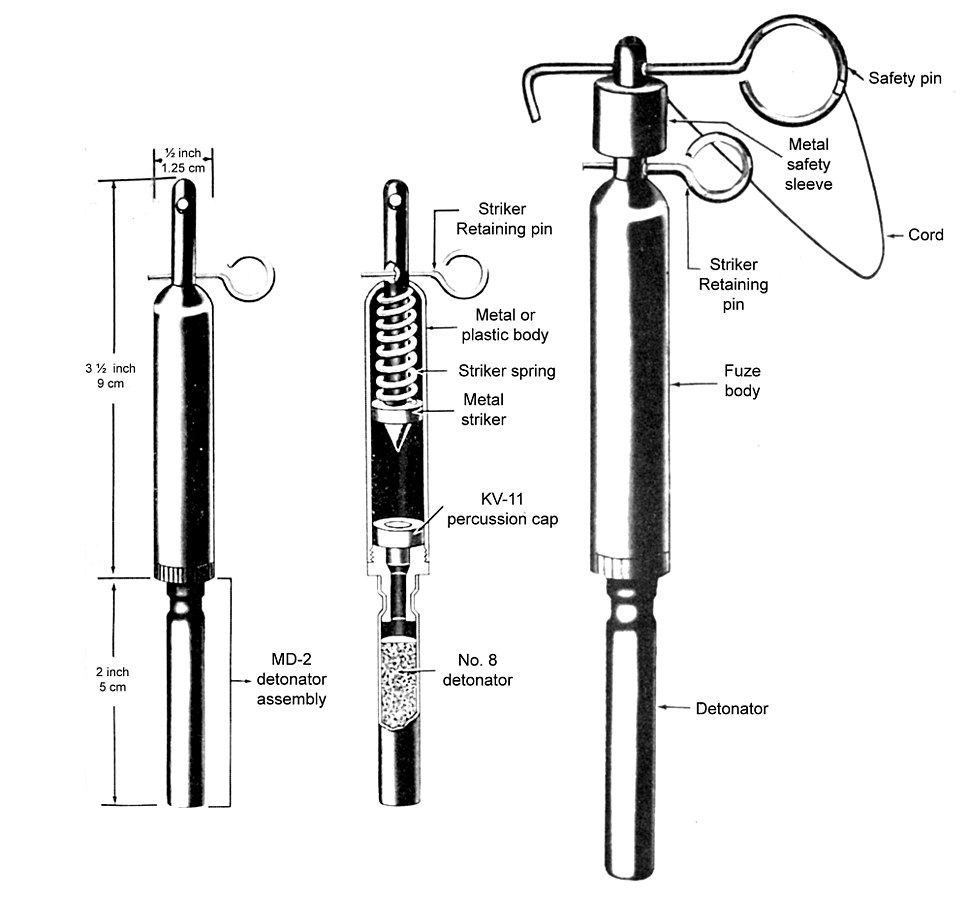

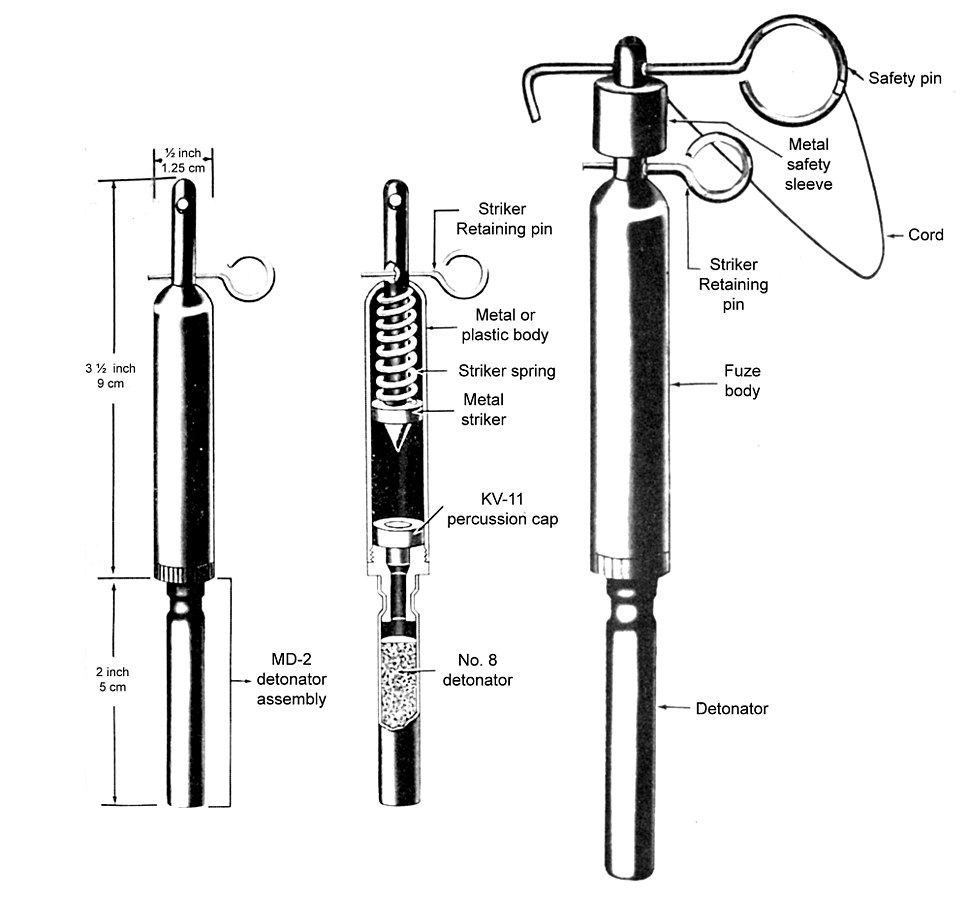

*The MUV (MYB) fuse was tubular in construction and could be activated by either pressure or by simply pulling. The body of the fuse contains an extended spring-loaded striker which can be held in compression by a safety pin, which, once removed, causes the striker to impact against the detonator, setting off an initial charge which in turn ignites the main charge. The fuse features a threaded section which enables it to be used with a variety of devices from the application here, through to boodytraps.

Back

The TM-35 was produced using zinc-plated steel and was rectangular in shape. The pressure plate, on the top, when compressed by the weight of a tank, would in turn depress a rocker switch that would remove an internal safety pin allowing for the MUV* fuse to activate the mine. 200 grams of TNT was packed in blocks, housed in divided sections inside the body of the mine.

The TM-35 was produced using zinc-plated steel and was rectangular in shape. The pressure plate, on the top, when compressed by the weight of a tank, would in turn depress a rocker switch that would remove an internal safety pin allowing for the MUV* fuse to activate the mine. 200 grams of TNT was packed in blocks, housed in divided sections inside the body of the mine.

Externally, the mine was provided with a carry handle for easy of transportation. It also featured four ridges on the pressure plate, which both allowed for the steel to be thinner than would otherwise be the case and acted as an anchor into the soil covering the top of the mine, preventing the wind from exposing the mine's location. Russian soil was generally lighter and finer soils than that of most countries, so this was a very real potential. Additionally, the TM-35 allowed for an additional fuse to inserted, which would work in tandem with the internal MUV full fuse making it harder for attacking troops to render the mine safe in advance of their tanks.

*The MUV (MYB) fuse was tubular in construction and could be activated by either pressure or by simply pulling. The body of the fuse contains an extended spring-loaded striker which can be held in compression by a safety pin, which, once removed, causes the striker to impact against the detonator, setting off an initial charge which in turn ignites the main charge. The fuse features a threaded section which enables it to be used with a variety of devices from the application here, through to boodytraps.

Back